The uses of UV light is exponentially increasing with the advent of new technology in applications such as in medical, water purification, adhesive materials, imagining, etc. This increase is requiring new probe designs for measuring and monitoring UV light to meet the needs of these new applications. What was once sufficient with a single point measuring probe has expanded to multiple points for measuring both intensity and energy across large surface areas. Also the shift from a UVA or UVB wavelengths to UVC wavelengths is requiring new filter designs to accurately and repeatably measure the UV lamp’s output. Both of these occurrences are being met by end users working with G&R Labs to design and produce new meters, probes and filters stacks to meet their application requirements.

Due to non-disclosure agreements, some of these companies must remain unnamed. However, we are able to show some of these new designs projects:

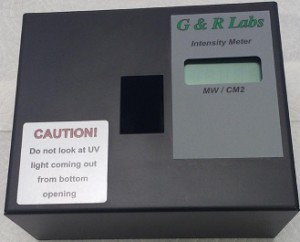

Model 204 replaces existing UV monitor

A major equipment manufacturer had a critical need to replace their current UV monitors with the following prerequisites: 1. accurate and repeatable measurements, 2. reliable, 3. little if any linearity error, 4. simultaneously monitor two separate measurements, 5. computer interface to record data measurements.

Using these perquisites, G&R Labs’ developed the Model 204 to meet these perquisites: 1. the original calibration is to the NIST standard as all re-calibrations ensuring accuracy and reliability. 2. The Model 204 design is based upon G&R labs’ units that have been in the field for over 20 years and are still being used, 3. The Model 204 has +/- 1% linearity over the range from 1.00 to 250.00 mw/cm2, 4. 2 sensors simultaneously monitor two separate measurements 5. A computer interface collects data once per second. Also, this unit incorporates a plug-in charger for 24/7-day operation.

G&R Labs is pleased to become Oak River’s OEM for measuring the system’s UV output. The Model 204 may be purchased from Oak River.

Contact information:

Sales

Oak River Technology

640 Hayward Ave N

Oakdale, MN 55128

(651) 395-5051

www.OakRiver.bis

Standard UV Light Meter Probe

The standard probe used with most of the meters is our hockey puck probe. The probe is 1.62 inch (41.1mm) in diameter by 0.59inch (15mm) thick. The probe has a 0.300inch (7.62mm) diameter measurement opening.

Dual Channel UV Light Meter Probe

The Dual Channel Probe has the same dimensions as the single channel probe, 1.62 inch (41.1mm) diameter by 0.59 (15mm) thick. The probe has two 0.300 inch (7.62) diameter measurement openings. You can use two different wavelengths in this probe. The probe works with the Model 202 or with the Model 325 meters.

Custom Designed 7 Sensor Channel Rail

This application requires measuring a broad rectangular surface area and recording the UV intensity (mw/cm2) levels across the area. The process also requires the UV output across this broad surface area be accurately measured to ensure a tightly specified uniformity level. Therefore, a significant challenge, in meeting this stringent requirement, is to calibrate each sensor to within +/- 1% or less to other individual sensors. The information from the UV sensors are then recorded by a computer for monitoring day to day activity to “track” any degradation with the UV lamps. The end user is successfully using the Channel Rail in production, today.

Each sensor in the 7 sensor array is calibrated to a NIST standard for accuracy and repeatability.

Specially Designed 11 Point Sensor Array

This sensor array is designed to meet a unique application requiring 11 sensors arrayed in a semi-circle configuration. The challenge once again is to calibrate all 11 sensors to within +/- 1% or less of one another. Also, the UV meter readout needed to display all 11 sensor readings simultaneously. Informational readout across the 11 point sensors included: mw/cm2, uniformity, average intensity value, display min, max and mid range intensity levels.

Each individual sensor in the 11 sensor array is calibrated to NIST standards for accuracy and repeatability.

UV Curing Measurement Meter for Labels

This unique measurement meter is designed for quality control to measuring the reflectance value (mw/cm2) of labels that will be attached to commercially available bottles of water sold in retail stores domestically and internationally.